The authentication and brand protection industries are not known, for obvious reasons, for their willingness to share information. But a chance meeting at a Reconnaissance conference between a client and supplier is beginning to bear fruit.

© Bundesdruckerei GmbH and Security Fibres Ltd.

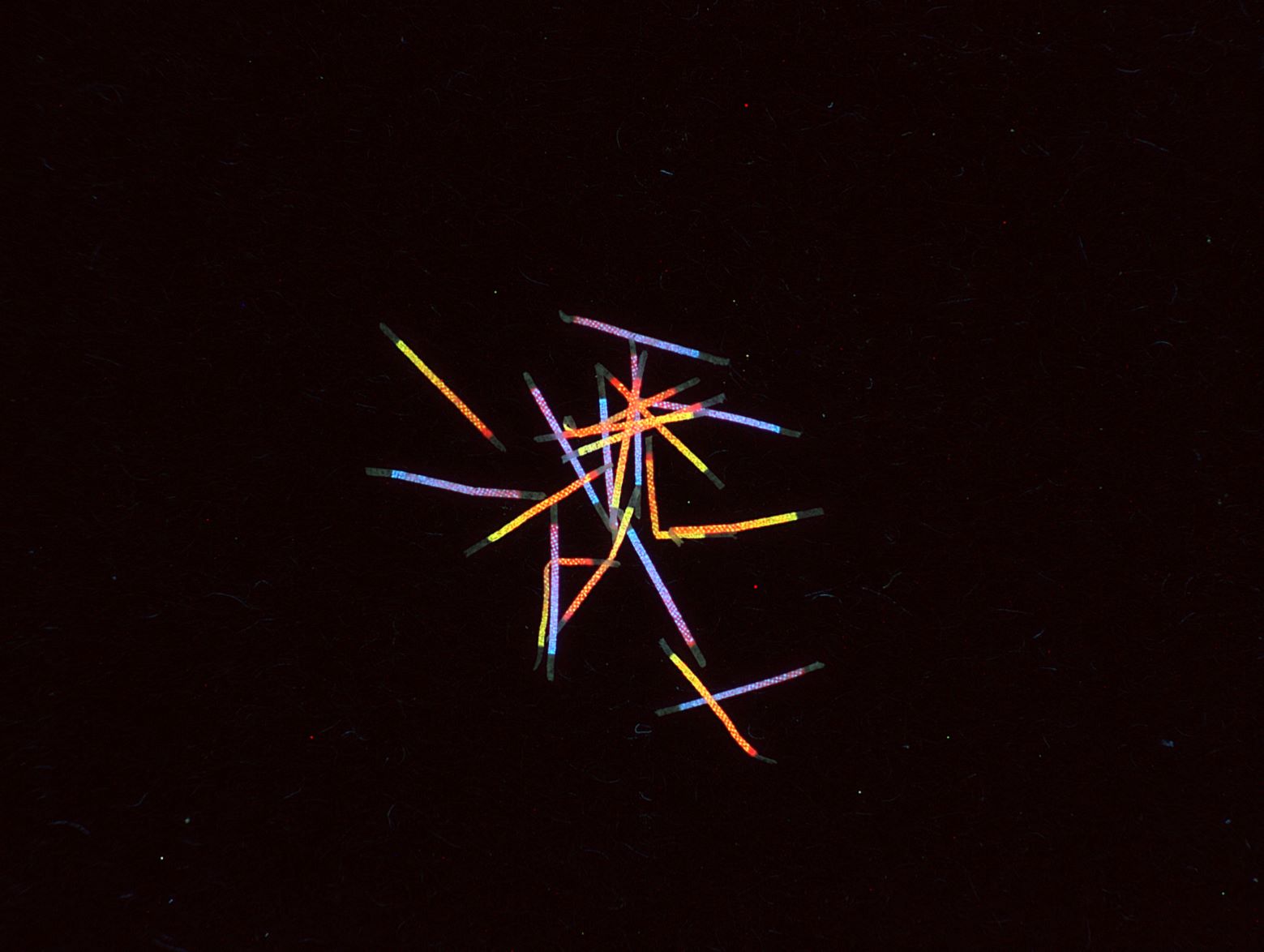

Four years ago, at the High Security Printing EMEA Conference in Malta, Duncan Faulkner (Bundesdruckerei, Germany) and Gary Spinks (Security Fibres, UK) sat down to talk about one of their favourite subjects – security fibres. These are short (typically 2mm-6mm), narrow (0.3mm to 3mm wide) lengths of material that are added to security paper pulp during the papermaking process and are a common feature in banknotes, passports and other secure documents.

‘I was musing with Gary about how the manufacturing process for UV-excited fibres could be adapted to create a colour gradient across the fibre. Each colour would be saturated on one side and less so on the other,’ Duncan said.

The two then began thinking about how the process might be controlled to create two distinctive colours on the same fibre and which colour combinations might create the most recognisable feature – and thereby present the hardest obstacle for simulation to the would-be counterfeiter.

The pair have been in the security print business for years, and so were acutely aware of the importance of fibres in protecting the supply chain for security papermaking.

‘Security paper mills are a niche group within an already select group of high-end paper manufacturers that are equipped to make watermarks and the other distinctive features that single out security paper as being special,’ Gary said. ‘Security fibres, and other specialist elements, not only raise the bar for counterfeiters but also act as a guarantee of the supply chain.’

Following this exchange of ideas, it was then time to create some prototypes. Obviously, due to the complexity of the production processes, the whole methodology for creating the colour gradient needed to be evaluated and optimised for the best performance under full production conditions and to ensure the highest reproduction quality. After some creative attempts and learning experiences, Duncan and Gary are confident that this new range provides a further enhancement in the world of security fibres.

‘It is pretty impressive how much security you can get into a 5mm fibre when you do it properly!’ Duncan said. ‘By working collaboratively, we have been able to create a new class of product – a further innovation on the existing multicoloured fibres that Security Fibres already produces. And that’s just the start – we are already working on additional forensic aspects that can be included.’